The performance and material requirements for CSP coupling systems are scattered among several ASTM and AASHTO specifications. The two most commonly used specifications for defining CSP coupling systems are Section 26 of the AASHTO LRFD Bridge Construction Specifications and ASTM A760, Standard Specification for Corrugated Steel Pipe, Metallic Coated for Sewers and Drains.

All CSP joining systems involve one of the coupling bands depicted in the table below and may require a flat or o-ring gasket.

| Most Common Coupling Bands for Corrugated Steel Pipe | |||||||||

| Type of Band | Cross Section | Angles | Bar, Bolt & Strap | Gaskets | Pipe Type | ||||

| O-Ring | Sleeve or Strip | Mastic | Annular | Helical | |||||

| Plain | Reformed | ||||||||

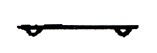

| Universal |  | X | X | X | X | X | X | X | |

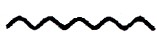

| Corrugated |  | X | X | X | X | X | X | X | |

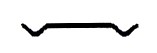

| Semi-Corrugated |  | X | X | X | X | X | X | ||

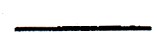

| Flat |  | X | X | X | X | X | X | X | |

Benefits of Corrugated Steel Pipe Joining Systems:

- Positive connections are available between joints which resist earth movement and joint separation

- Gasketed coupler connections perform to stringent infiltration and exfiltration requirements of current design standards

- Special couplers can be tailored to a variety of installation circumstances