By: TrueNorth Steel

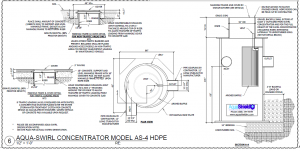

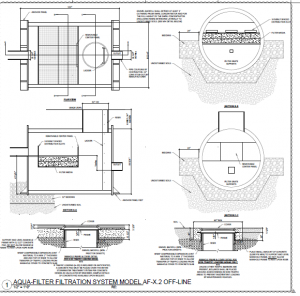

Discharging runoff into a creek requires an added level of treatment through filtration to target finer particles. The treatment train for Hallstrom’s consisted of an AquaShield AS(AquaSwirl)-4 84in diameter x 14ga 5×1 polymeric coated hydrodynamic separator for pretreatment of the stormwater prior to entering the detention system to remove trash, sediment and oils. Additionally, an AquaShield AF-4.2 77inx52inx12ga polymeric coated pipe arch media filter was selected to treat discharge from the detention system prior to entering Spring Creek.

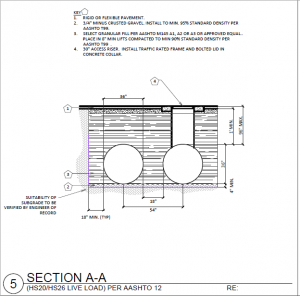

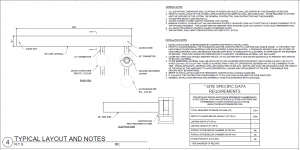

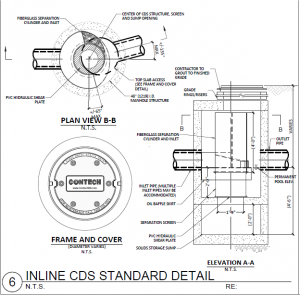

The original plans called out an Aluminized Type II Detention System (see exhibit 1,2&3) and an inline Concrete Continuous Deflection Separator (see exhibit 4). AquaShield designs and tests stormwater treatment systems to meet challenges associated with post construction runoff. TrueNorth Steel partners with AquaShield to specify, sell and manufacture these systems.

The original plans called out an Aluminized Type II Detention System (see exhibit 1,2&3) and an inline Concrete Continuous Deflection Separator (see exhibit 4). AquaShield designs and tests stormwater treatment systems to meet challenges associated with post construction runoff. TrueNorth Steel partners with AquaShield to specify, sell and manufacture these systems.

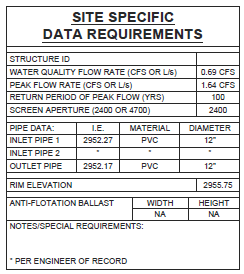

The City of Kalispell follows the Washington Department of Ecology as part of their approval process for mechanical stormwater treatment devices. AquaSwirl has a General Use level Designation for Pre-Treatment in stormwater detention applications. The AquaSwirl met the Water Quality Treatment Flow and Volume of runoff (see exhibit 5) that has been verified by third party testing and we were approved for the project (see exhibit 6).

Following a project award to Lipka Excavation, Montana DEQ stepped in and required post treatment of the detained stormwater into Spring Creek. Working with AquaShield and Jackola Engineering, we were able to obtain an approval for an AquaFilter AF-4.2(see exhibit 7).

Following a project award to Lipka Excavation, Montana DEQ stepped in and required post treatment of the detained stormwater into Spring Creek. Working with AquaShield and Jackola Engineering, we were able to obtain an approval for an AquaFilter AF-4.2(see exhibit 7).

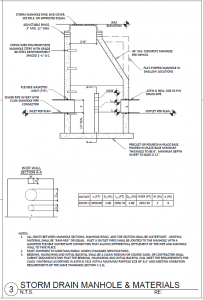

TrueNorth Steel assisted the owner with eliminating the added cost and weight of two concrete structures with the separator and filter by utilizing Corrugated Steel Pipe. However, the filtration system was an unexpected cost to the owner. To help further offset the unexpected cost, a value engineering opportunity was identified to eliminate an additional or third concrete manhole (see exhibit 8). The storm drain manhole was located between the detention system and the AquaFilter. By value engineering a TrueNorth Steel Flow Control Tee and incorporating it as part of the detention system (see exhibit 9), the concrete storm drain manhole was no longer needed and deleted from the project.

TrueNorth Steel met all project specifications and successfully assisted the owner by bringing value to their project without compromising service life.

Exhibit 1

Exhibit 2

Exhibit 3

Exhibit 4

Exhibit 5

Exhibit 6

Exhibit 7

Exhibit 8

Exhibit 9