Aluminum Coated Type 2 (AASHTO M274, ASTM A929) is a pure aluminum coating (no more than 0.35 percent silicon). It is produced with a coating weight of 305 g/m² (1 oz/ft²) of surface (total both sides) to provide a coating thickness of 48 µm (0.0019 in.) on each surface. The aluminum coated type 2 (ALT2) is the most widely used supplemental coating for CSP. “Aluminum is a reactive metal, but it develops a passive aluminum oxide coating or film that protects it from corrosion in many environments.” This film is quite stable in neutral and many acid solutions but is attacked by alkalies greater than a pH of 9. From a corrosion standpoint, aluminum has an advantage over galvanized in lower pH and in soft water conditions due to the formation of the oxide film. The coatings are essentially equal under abrasion and in waters where the zinc oxide film forms rapidly.

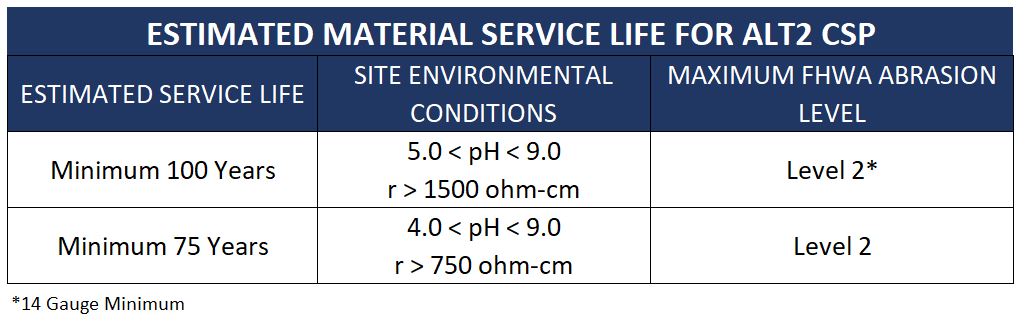

Aluminum Coated Type 2 (AASHTO M274, ASTM A929) is a pure aluminum coating (no more than 0.35 percent silicon). It is produced with a coating weight of 305 g/m² (1 oz/ft²) of surface (total both sides) to provide a coating thickness of 48 µm (0.0019 in.) on each surface. The aluminum coated type 2 (ALT2) is the most widely used supplemental coating for CSP. “Aluminum is a reactive metal, but it develops a passive aluminum oxide coating or film that protects it from corrosion in many environments.” This film is quite stable in neutral and many acid solutions but is attacked by alkalies greater than a pH of 9. From a corrosion standpoint, aluminum has an advantage over galvanized in lower pH and in soft water conditions due to the formation of the oxide film. The coatings are essentially equal under abrasion and in waters where the zinc oxide film forms rapidly.Aluminum coated type 2 CSP has been installed at thousands of sites over the past 50 years and many of these sites have been and are still being monitored for performance. Recent AK Steel research has indicated that 14 gage ALT2 CSP can achieve a 100-year service life when the environmental conditions have a pH of 5 to 9 and a resistivity greater than 1500 ohm-cm.

For more information download our Pipe Selection Guide found here.

DOT Information

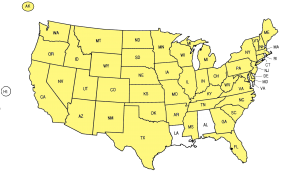

The below is a map of the states that currently accept ALT2 coated pipe and plate in their specs.

Success Stories

By: Lane Enterprises, Inc Steelpointe is a 37 acre mixed housing development on the former industrial site of Phoenix Iron…

By: TrueNorth Steel Irrigation is serious business to farmers and ranchers in the arid western U.S.. Irrigation water loss means…

By: Southeast Culvert This project was originally designed as a plastic chamber infiltration system. Southeast Culvert was asked to propose…

By: Contech Engineered Solutions The Pat Millikan Ford Dealership had outgrown its current property and needed more space, so they…

By: J & J Drainage Butler County Public Works Dept. needed to replace a deteriorated structure consisting of reinforced concrete…

Studies, Resources & Marketing Materials

- The Measured Performance of Aluminized Type 2 Steel Pipe in Storm Sewer Applications in the North Georgia Region – A research project on the durability of Aluminized Steel Type 2 pipe

installed in the metro Atlanta area has resulted in an outstanding report of the product’s performance.

installed in the metro Atlanta area has resulted in an outstanding report of the product’s performance. - Durability of Aluminized Type 2 Corrugated Steel Pipe Exposed Throughout the United States – A report by Elzly Technology Corporation documenting the performance and environmental conditions of aluminized type 2 coated CSP in 11 states and parts of Canada.

- Service Life – ALT2 Field Reports

- EFFECTS OF GAGE ON PIPE DURABILITY: Based on 75 Years Minimum Service Life at 16 Gage – For Worst-Case Conditions Within The Recommended pH/Resistivity Ranges

- Meeting New Durability Standards and Expanding Environmental Limits with Corrugated Steel Pipe

- The Measured Performance of Aluminized Type 2 Steel Pipe in Storm Sewer Applications in the North Georgia Region – A research project on the durability of Aluminized Steel Type 2 pipe

installed in the metro Atlanta area has resulted in an outstanding report of the product’s performance.

installed in the metro Atlanta area has resulted in an outstanding report of the product’s performance.