By: Pacific Corrugated Pipe Co.

An Unexpected Call: Laying the Groundwork for Polar Innovation

On a seemingly ordinary January day in 2015, Pacific Corrugated Pipe (PCP) received an inquiry from Lockheed Martin that would, in due course, lead to an extraordinary project. Specifically, Lockheed Martin sought information regarding PCP’s culvert capabilities, foreshadowing a mission of unprecedented scope. Accordingly, after a series of detailed phone calls and email exchanges, a product design was approved, effectively clearing the path for the deployment of robotic submarines through the formidable Antarctic Ice Shelf. Indeed, the utilization of corrugated steel caissons was pivotal for this ambitious undertaking.

Crafting for the Cold: Precision Engineering of the Caissons

To facilitate this groundbreaking mission, PCP designed and built two caisson sleeves, each engineered for the harsh Antarctic environment. First, they created a sleeve approximately 4 feet in diameter, followed by a slightly larger one, about 4.5 feet in diameter. Each sleeve measured a substantial 15 feet in length, constructed from 10-gauge polymer-coated corrugated steel pipe. This precise length, 15 lineal feet, proved crucial to provide a stable and sufficient sleeve within the thick Antarctic ice shelf. Similarly, they selected the material and coating to withstand the extreme cold and potential corrosion. Thus, the integrity of the corrugated steel caissons was paramount for the mission’s success.

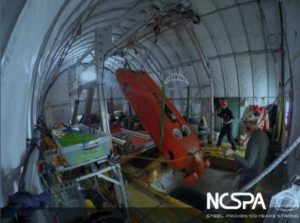

A Journey to the Frozen South: Transporting Innovation

Once the fabrication was complete, the sleeves, along with members of the scientific team, were transported via a C-17 aircraft from sunny Southern California to the McMurdo Station research center. This research center, operated by the National Science Foundation, served as the gateway to the icy depths. Subsequently, the sleeves were installed vertically through the ice shelf, creating a vital access point. Moreover, these sleeves allowed the ARTEMIS submarine to descend into and be retrieved from the waters beneath the ice. Therefore, the efficient transport and installation of the corrugated steel caissons were critical for the project’s logistics.

Triumph Beneath the Ice: Data, Samples, and Mission Success

Ultimately, the product proved to be a resounding success, facilitating the flawless launch and retrieval of the ARTEMIS robotic submarine. In due course, the crew successfully acquired the necessary samples and data, marking a significant milestone in Antarctic research. Following this accomplishment, the team departed the location, retreating before the onset of the harsh winter. In short, the corrugated steel caissons performed flawlessly, enabling the successful completion of the subsea exploration.

Beyond Conventional Use: The Versatility of Corrugated Steel

While Pacific Corrugated Pipe considered this project a relatively small undertaking, the application proved undeniably extraordinary. Even though they didn’t use the product for its traditional purpose of storm drainage, it demonstrated the versatility of corrugated steel pipe (CSP). This project highlighted the countless unconventional applications of CSP, many of which people often overlook. Consequently, it serves as a testament to the adaptability and innovation that engineers can achieve with this material. In conclusion, the use of corrugated steel caissons and the caisson sleeves in this Antarctic mission showcased the boundless potential of engineering solutions.

Related Stories

Project Spotlight: Florida CMP Sleeves

2023 Project of the Year – Special Application Winner: SoFi Stadium

Project Spotlight: Grand Car Wash Detention System