By: Lane Enterprises, LLC

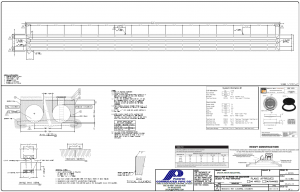

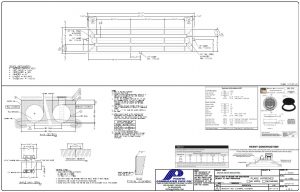

A large tilt-up Industrial Park located in Rancho Cucamonga, California required two large, multi-barrel retention systems to support the storm water management plan for this property. Both systems utilized fully-perforated  60” diameter 16 gage 5” x 1” Aluminized Type 2 corrugated steel pipe. The first system was a smaller 3-barrel system and contained 286 feet of 60” pipe. The larger of the two systems was a 4-barrel system requiring the same 60” fully-perforated pipe, but the total length of the pipe needed for this system was over 1,800 feet. To join the barrels together required a multitude of fittings that varied from 18” to 36” in diameter. Also, since the pipe was manufactured using fully perforated raw material coils, we were able to pull the individual barrels directly from our mill to the delivery vehicles with no additional handling required. The efficiency of production allowed Lane Enterprises, LLC to complete delivery of all retention system products for this development site within 15 working days from the start to end of deliveries. Once completed, the project represented a total of 50 tons of corrugated steel pipe including the various fittings, and the result is a cost-efficient storm water management retention system

60” diameter 16 gage 5” x 1” Aluminized Type 2 corrugated steel pipe. The first system was a smaller 3-barrel system and contained 286 feet of 60” pipe. The larger of the two systems was a 4-barrel system requiring the same 60” fully-perforated pipe, but the total length of the pipe needed for this system was over 1,800 feet. To join the barrels together required a multitude of fittings that varied from 18” to 36” in diameter. Also, since the pipe was manufactured using fully perforated raw material coils, we were able to pull the individual barrels directly from our mill to the delivery vehicles with no additional handling required. The efficiency of production allowed Lane Enterprises, LLC to complete delivery of all retention system products for this development site within 15 working days from the start to end of deliveries. Once completed, the project represented a total of 50 tons of corrugated steel pipe including the various fittings, and the result is a cost-efficient storm water management retention system

for the Santa Anita Industrial Park.