We are proud to say that Steel holds the title of the most sustainable storm water solution on the market today. It is 100 percent recyclable, which means it can be recycled into the same material of the same quality again and again. Because of the ease of separation from other metals due to its magnetic properties, millions of tons of steel are pulled from waste centers each year and recycled into new steel products such as steel beams, refrigerators, car doors, roof panels and storm water solution products. Even with continued reuse, steel’s strength, durability, versatility and performance never waivers. But how exactly does steel stack up against the competition?

Production

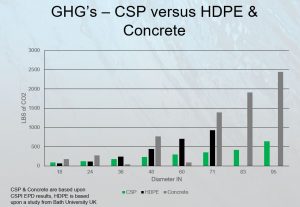

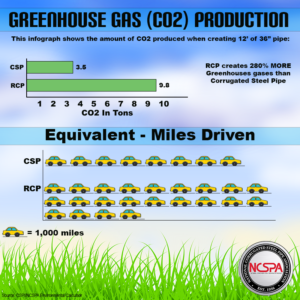

Over 1.5 billion tons of steel is produced around the globe annually. Most production takes place via 2 methods: a Basic Oxygen Furnace (BOF – 70% of production) or an Electric Arc Furnace (EAF – 30% of production). The steel that is produced for corrugated steel products is primarily smelted using Electric Arc Furnaces. Electric Arc Furnaces primarily use recycled materials such as refrigerators, cars and even other corrugated metal pipes. Because steel retains it’s strength after even after recycling, scrap steel can be used repeatedly resulting in a 96% efficiency rating from raw material to finished product. The production of steel in North America has changed dramatically over the past few decades. The energy required to produce one ton of steel today requires less than half the energy it did 40 years ago. This results in a reduction of 50% in green house gas (GHG) emissions. So what does that mean? A single ton of steel produced today uses the same amount of GHG as driving a car for 2,000 miles! When compared to the competition, Steel has been shown to use half the amount of GHG as RCP. For example, production of 1 metre of 18″ corrugated steel pipe creates 88.18 lbs of CO2 which is the equivalent of driving 98.18 miles or 1.6 standard propane tanks. When compared to RCP, that same 1 metre of 18″ concrete pipe production creates 176.37 lbs of CO2, which equals 193.87 miles driven or 3.3 propane tanks! For more information on the GHG emission of Steel vs it’s competitors check out the Environment Product Declaration by the Corrugated Steel Pipe Institute of Canada here. This EPD is fill with additional information on steel’s sustainable nature as compared to its top competitors. You can also check out our Environmental Calculator here. This handy calculator shows you the amount of CO2 produced (in tonnes) by CSP & RCP in relation to length and width of the pipe.

Environmental Calculator

Transportation

Transportation

Corrugated steel products also help cut down on pollution during transportation. A key feature of CSP is it's ability to be stacked and nested without damaging the pipe. This allows for more pipe to be transported to the job site at once resulting in fewer overall trips. CSP can be transported via truck, train and even, on occasion, via helicopter! When needed, corrugated steel pipe can even be produced right on site with the use of mobile mills.

End Of Life

When steel has reached the end of it's life it is able to be recycled back into the stream. This recycled steel is taken to recycling centers for separation and transportation to steel mills to begin the journey all over again. Steel has been noted by the Steel Recycling Institute to be the engine that drives the recycling of many consumer goods. Over 95 percent of automobiles, 88 percent of appliances and 70 percent of steel packaging is recycled annually which results in two out of three tons of new steel being produced from recycled steel. By-products of steel manufacturing can also be used to process other materials. Steel slag is commonly used in the concrete industry as a replacement for fine and coarse aggregates. The compressive and tensile strength of concrete has been shown to improve when steel slag was used during production. Along the same lines, steelmaking dusts and sludges can be processed to the point where other metals, like zinc, are able to be recovered and reused. For more information on how steel is recycled and reused check out this educational video from our friends at Cleveland Cliffs (formally AK Steel).

NCSPA Presents Smarter, Stronger, Sustainable Steel - Full Video

Real Deal On Steel Live Webinar #5 - Sustainability

NCSPA Presents Smarter, Stronger, Sustainable Steel - Cement Production Short

Links

For more information be sure to check out the following resources:

- Corrugated Steel Pipe Institute: CSP Sustainability

- American Iron & Steel Institute: Sustainability

- American Institute of Steel Construction: Sustainability

- Build Using Steel: Sustainability

Literature:

Steel Recycling: