Steel’s Resiliency

“Resilience” is defined as a structure’s ability to meet extreme natural and man-made challenges with minimal disruption to occupants and functions. With that in mind, did you know that Steel’s durability, noncombustibility and strength make it an inherently resilient design material? It’s true! Steel is a unique resource as its homogenous and isotropic properties assure consistent, predictable performance and confidence in design. What does that mean exactly? It means that the reserve strength of steel provides inherent additional resistance to the forces caused by natural disasters and man-made extreme events. In addition, the ductility of steel allows for redistribution of forces (when necessary) to provide an alternate structural load path or to accommodate displacements caused by natural disasters and man-made extreme events. Steel also provides strength, structural integrity and resilience for other materials’ systems (e.g., reinforcing steel in concrete construction and steel connectors in wood frame construction), making it a logical choice for the whole structural system.* For more information on Steel’s resiliency check out the SFIA’s “Cold-Formed Steel and Resilience” Issue Paper, May 2015.

Pipes Under Pressure

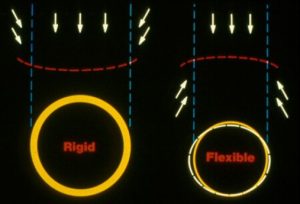

Excessive seismic movements can cause brittle failures in rigid pipes such as RCP. These failures can lead to fracturing and cracking propagation. In addition the low tensile strength and low resistance to shear forces and lateral movement causes failures among rigid pipe.

How CSP Holds Its Ground

CSP joints must comply with the mechanical requirements of ASTM A798. This provides minimum values for joint performance including shear, movement, and pull-apart capacity. Rigid pipe, such as RCP, does not have such a requirement. Because RCP joints possess minimum resistance to pull-apart forces, their ability to withstand lateral movement and loads resulting from differential settlement is severely diminished.

How Can Steel Aid In An Emergency

How Can Steel Aid In An Emergency

Corrugated Steel Pipe can be used as slip lining for the failed concrete structure by sliding the CSP inside on skids or rails and using internal bands then grouting the gap between the concrete and metal structure.

Seismic Analysis Procedure for Corrugated Metal Buried Structures

This report, a collaborative effort by the National Corrugated Steel Pipe Association (NCSPA) and Simpson Gumpertz & Heger Inc. (SGH), with contributions from industry leaders like Contech Engineered Solutions, Lane Enterprises, and the American Iron and Steel Institute (AISI), presents groundbreaking research in the field of buried structure design. It introduces a simplified yet robust methodology for estimating seismic demands on arch-shaped corrugated metal structures, a critical aspect often overlooked in current design codes.

With the increasing prevalence of large-span buried structures, the need for efficient and reliable seismic design tools has never been greater. This report addresses this need by providing closed-form equations, derived from meticulous finite element analyses, that allow engineers and designers to readily assess seismic thrust and moment demands. These equations consider key factors such as soil properties, structural dimensions, and fill depth, offering a practical alternative to complex and time-consuming soil-structure interaction analyses.

Download the full report today to delve into the research methodology, explore illustrative design examples, and discover proposed code modifications that could revolutionize the way we design and construct buried structures in seismically active regions.

Pipes & Heavy Stormwater

Pipes & Heavy Stormwater

During heavy downpours water can start to saturate the backfill material causing it to lose structural support. Once the backfill material becomes unstable it can eventually wash away leaving the pipe or bridge unsupported. Without any support the pipe can wash away or become damaged.

How CSP Can Prevent Flooding

Properly backfilled and installed steel pipe/structures can perform well when flooding occurs. When properly installed, steel will not float unlike alternative plastic pipes. Steel can be designed with a variety of end treatments to help facilitate water running through the pipe/structure vs. underneath or into the backfill zone – which could wash the pipe away.

How Can Steel Aid In An Emergency

How Can Steel Aid In An Emergency

Steel is easy to handle, quick to manufacture and quick to install. Heavy equipment is typically not needed when installing CSP whereas heavier pipe such as concrete usually requires heavy construction equipment. The use of mobile mills for on site fabrication helps to cut down on construction times even more!

Case Study

Labette County Bridge 183 Replacement by Contech Engineered Solutions

CSP Keeping You Safe During The Darkest Hours

CSP Keeping You Safe During The Darkest Hours

Corrugated steel is gaining wider appeal for special uses because the aluminized steel used in these structures is both long lasting, structurally sound, and relatively inexpensive compared to other product options. How CSP Stands Strong Against The Winds CSP structures exceed the standards set by FEMA 320 and FEMA 361. These durable structures can be built with an attached steel door for installations in the side of an embankment, or with vertical access risers. A variety of access stubouts can be attached to the structure to allow the owner to install ventilation systems or even electrical systems.

Forged In The Flames

Steel is noncombustible, so it does not contribute to the ignition of fires, the spread of fires, or the size and severity of fires, thus reducing risks to occupants, firefighters and property/business owners. Steel is forged from fire and will not begin to lose strength or elasticity below 400°F (200°C), while concrete begins losing strength and 200°F (93°C), and plastic at 86°F (30°C). With the temperature of wildfires burning hotter than 800°C (1470°C), steel and concrete will maintain a small percentage of their yield strength. But if the drainage structure becomes engulfed by fire plastic will ignite. If the fire stays at a range with temperatures burning between 800°F (430°C) and 1400°F (760°C) steel will maintain 94% of its yield strength down to 16% at these temperatures. Concrete goes from 70% to 10%. Additionally, once the fire has moved on, steel will regain all of its strength post fire while concrete will lose from 20 to 40%.

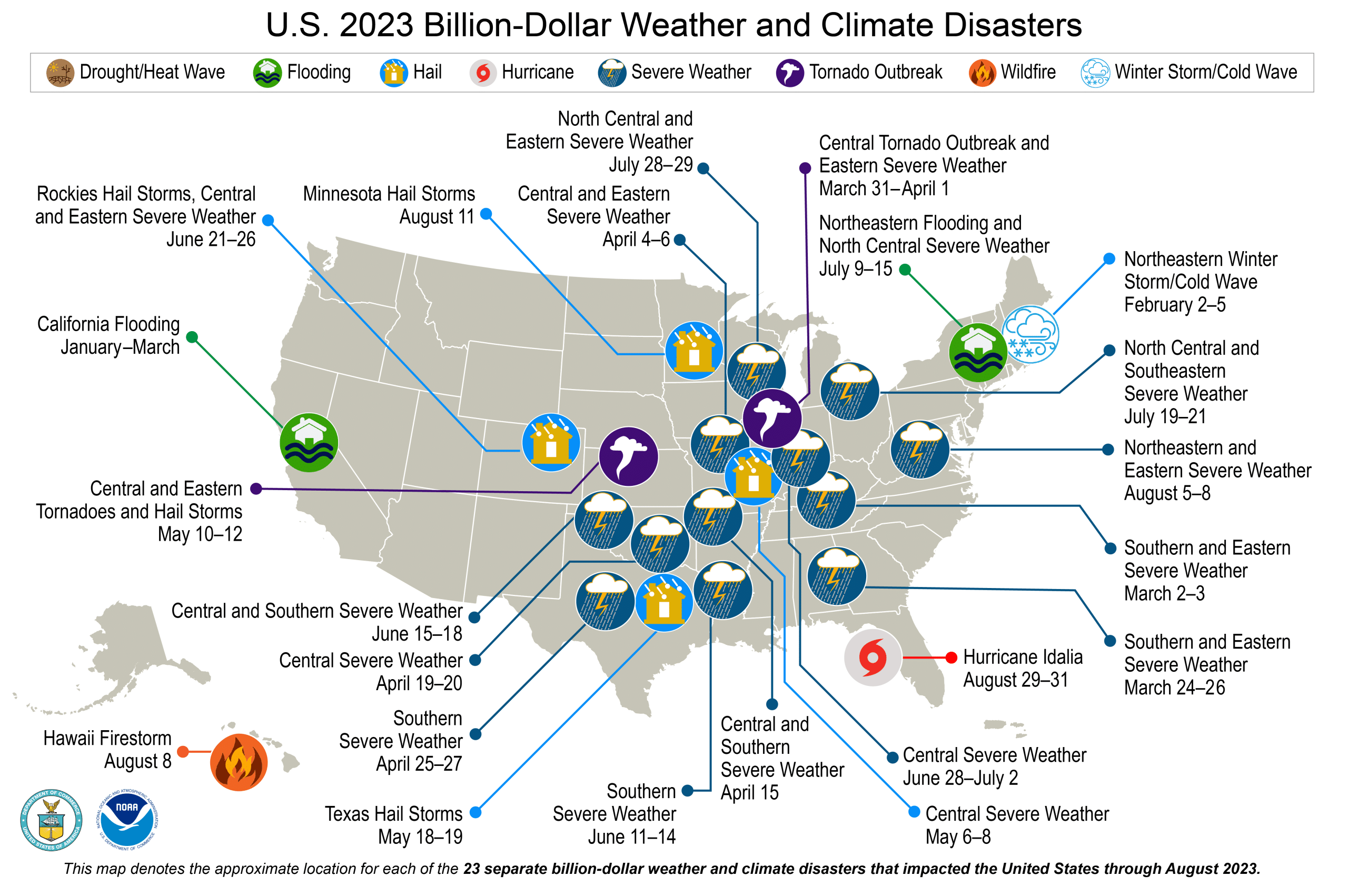

Regional Impacts

| Threat | Vulnerability (Vt) | Risk Rating (Rt) | Total Possible Risk (TPR) | ||

| Risk Level (Pt) | |||||

CSP | Severe Storm | 0.6 | 12.5% | 0.6 | 4.8 |

| Extreme Flood Event | 0.4 | 14.9% | 0.6 | 4.2 | |

| Hurricane | 0.2 | 7.2% | 0.4 | 5.2 | |

| Wildfire | 0.6 | 7.1% | 0.2 | 1.8 | |

| Earthquake | 0.2 | 8.0% | 0.1 | 2.4 | |

| Climate Change | 0.6 | 16.0% | 0.1 | 0.8 | |

| Total Risk Index, Rc | 10.7% | 2.0 | 19.2 | ||

| Risk Level (Pt) | |||||

RCP | Severe Storm | 0.6 | 12.0% | 0.6 | 4.8 |

| Extreme Flood Event | 0.4 | 12.6% | 0.5 | 4.2 | |

| Hurricane | 0.2 | 6.3% | 0.3 | 5.2 | |

| Wildfire | 0.6 | 7.1% | 0.1 | 1.8 | |

| Earthquake | 0.2 | 20.7% | 0.5 | 2.4 | |

| Climate Change | 0.6 | 32.0% | 0.3 | 0.8 | |

| Total Risk Index, Rc | 12.0% | 2.3 | 19.2 | ||

| Risk Level (Pt) | |||||

HDPE | Severe Storm | 0.6 | 11.5% | 0.6 | 4.8 |

| Extreme Flood Event | 0.4 | 15.2% | 0.6 | 4.2 | |

| Hurricane | 0.2 | 7.4% | 0.4 | 5.2 | |

| Wildfire | 0.6 | 39.1% | 0.7 | 1.8 | |

| Earthquake | 0.2 | 16.0% | 0.4 | 2.4 | |

| Climate Change | 0.6 | 32.0% | 0.3 | 0.8 | |

| Total Risk Index, Rc | 15.2% | 2.9 | 19.2 | ||

*Reference – A Holistic Approach to Evaluating the Sustainability and Resiliency of Buried Drainage Structures Relative to

Climate Change, TRB 2022 Annual Meeting, Dr. Michael Pluimer

| Threat | Vulnerability (Vt) | Risk Rating (Rt) | Total Possible Risk (TPR) | ||

| Risk Level (Pt) | |||||

CSP | Severe Storm | 0.6 | 12.5% | 0.6 | 4.8 |

| Extreme Flood Event | 0.4 | 14.9% | 0.6 | 4.2 | |

| Hurricane | 0.2 | 7.2% | 0.4 | 5.2 | |

| Wildfire | 0.6 | 5.3% | 0.1 | 1.8 | |

| Earthquake | 0.2 | 4.0% | 0.1 | 2.4 | |

| Climate Change | 0.6 | 12.0% | 0.1 | 0.8 | |

| Total Risk Index, Rc | 9.8% | 1.9 | 19.2 | ||

| Risk Level (Pt) | |||||

RCP | Severe Storm | 0.6 | 12.0% | 0.6 | 4.8 |

| Extreme Flood Event | 0.4 | 12.6% | 0.5 | 4.2 | |

| Hurricane | 0.2 | 6.3% | 0.3 | 5.2 | |

| Wildfire | 0.6 | 5.3% | 0.1 | 1.8 | |

| Earthquake | 0.2 | 10.3% | 0.2 | 2.4 | |

| Climate Change | 0.6 | 24.0% | 0.2 | 0.8 | |

| Total Risk Index, Rc | 10.3% | 2.0 | 19.2 | ||

| Risk Level (Pt) | |||||

HDPE | Severe Storm | 0.6 | 11.5% | 0.6 | 4.8 |

| Extreme Flood Event | 0.4 | 15.2% | 0.6 | 4.2 | |

| Hurricane | 0.2 | 8.2% | 0.4 | 5.2 | |

| Wildfire | 0.6 | 29.3% | 0.5 | 1.8 | |

| Earthquake | 0.2 | 9.7% | 0.2 | 2.4 | |

| Climate Change | 0.6 | 24.0% | 0.2 | 0.8 | |

| Total Risk Index, Rc | 13.4% | 2.5 | 19.2 | ||

*Reference – A Holistic Approach to Evaluating the Sustainability and Resiliency of Buried Drainage Structures Relative to

Climate Change, TRB 2022 Annual Meeting, Dr. Michael Pluimer

| Threat | Vulnerability (Vt) | Risk Rating (Rt) | Total Possible Risk (TPR) | ||

| Risk Level (Pt) | |||||

CSP | Severe Storm | 0.6 | 12.5% | 0.6 | 4.8 |

| Extreme Flood Event | 0.6 | 22.3% | 0.9 | 4.2 | |

| Hurricane | 0.6 | 21.7% | 1.1 | 5.2 | |

| Wildfire | 0.2 | 1.8% | 0.0 | 1.8 | |

| Earthquake | 0.2 | 4.0% | 0.1 | 2.4 | |

| Climate Change | 0.8 | 16.0% | 0.1 | 0.8 | |

| Total Risk Index, Rc | 15.2% | 2.9 | 19.2 | ||

| Risk Level (Pt) | |||||

RCP | Severe Storm | 0.6 | 12.0% | 0.6 | 4.8 |

| Extreme Flood Event | 0.6 | 18.9% | 0.8 | 4.2 | |

| Hurricane | 0.6 | 18.9% | 1.0 | 5.2 | |

| Wildfire | 0.2 | 1.8% | 0.0 | 1.8 | |

| Earthquake | 0.2 | 10.3% | 0.2 | 2.4 | |

| Climate Change | 0.8 | 32.0% | 0.3 | 0.8 | |

| Total Risk Index, Rc | 15.0% | 2.9 | 19.2 | ||

| Risk Level (Pt) | |||||

HDPE | Severe Storm | 0.6 | 11.5% | 0.6 | 4.8 |

| Extreme Flood Event | 0.6 | 22.9% | 1.0 | 4.2 | |

| Hurricane | 0.6 | 22.2% | 1.2 | 5.2 | |

| Wildfire | 0.2 | 9.8% | 0.2 | 1.8 | |

| Earthquake | 0.2 | 8.0% | 0.3 | 2.4 | |

| Climate Change | 0.8 | 32.0% | 0.3 | 0.8 | |

| Total Risk Index, Rc | 17.1% | 3.3 | 19.2 | ||

*Reference – A Holistic Approach to Evaluating the Sustainability and Resiliency of Buried Drainage Structures Relative to

Climate Change, TRB 2022 Annual Meeting, Dr. Michael Pluimer

Resources:

- Seismic Analysis Procedure for Corrugated Metal Buried Structures

- TRB Resilience: Key Products & Projects

- Resilience in Transportation Planning, Engineering, Management, Policy, and Administration

- Standing Committee on Culverts, Buried Bridges and Soil Structure Interaction

- *AISI: Strength & Resilience

- AISC: Resilience

- Cold-Formed Steel and Resilience” Issue Paper, May 2015.

- ASTM E60.80, WK71997 Resilience-Based Design of Culvert and Storm Drain Pipe Systems Exposed to Extreme Flood Events

- ASTM E60.80, WK77797 Resilience-Based Design of Culvert and Storm Drain Pipes Exposed to Wildfire Events