The durability of a drainage system is an important consideration for a civil engineer. As a result of continued interest in improving the durability of corrugated steel pipe (CSP) products, the CSP industry has sponsored extensive research over the past several decades on improved coating materials.

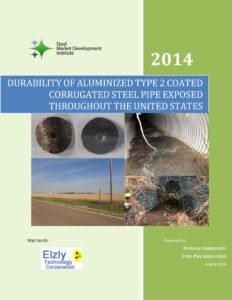

Aluminized Type 2 CSP was developed in 1952 to be a more durable coating than zinc in many of the common installation environments. In the early 1950’s, over 125 Aluminized Type 2 corrugated steel pipes were installed through a collaborative effort of Armco, now AK, Steel and over 20 county and state highway departments. Starting at the anniversary of 30 years of service, an inspection was conducted approximately every 10 years thereafter to track the performance of specific installations. Since that time, the material performance of sites in Maine, Maryland, Michigan, Ohio, Iowa, Illinois, Missouri, Mississippi, Alabama, Georgia, South Carolina, Louisiana, Texas, Kansas, Oklahoma, Colorado, Oregon, Utah, New Mexico, California and Washington have been documented. These studies, in addition to the work conducted by the Federal Highway Administration (FHWA) and multiple state DOT’s have continued to demonstrate the durability of Aluminized Type 2 CSP.

Aluminized Type 2 CSP was developed in 1952 to be a more durable coating than zinc in many of the common installation environments. In the early 1950’s, over 125 Aluminized Type 2 corrugated steel pipes were installed through a collaborative effort of Armco, now AK, Steel and over 20 county and state highway departments. Starting at the anniversary of 30 years of service, an inspection was conducted approximately every 10 years thereafter to track the performance of specific installations. Since that time, the material performance of sites in Maine, Maryland, Michigan, Ohio, Iowa, Illinois, Missouri, Mississippi, Alabama, Georgia, South Carolina, Louisiana, Texas, Kansas, Oklahoma, Colorado, Oregon, Utah, New Mexico, California and Washington have been documented. These studies, in addition to the work conducted by the Federal Highway Administration (FHWA) and multiple state DOT’s have continued to demonstrate the durability of Aluminized Type 2 CSP.

The present study was focused on documenting performance of Aluminized Type 2 CSP in long term installations as well as determining the viability of current technologies for measuring steel and coating thicknesses. Sites in this study were selected from AK Steel’s 50-year report, FHWA’s report titled “Durability Analysis of Aluminized Type 2 Corrugated Metal Pipe.”, and manufacturer records. In total, 26 core samples were removed and analyzed for coating thickness, pit depth, and alloy layer. These samples of both helical and riveted pipe ranged between 30 and 60 years in service. Soil and water samples were gathered from the site and analyzed for resistivity, pH and chlorides when available.

The data confirms current service life guidance for Aluminized Type 2 CSP, where 16 gage steel provides a minimum of 75 years of service life when the FHWA abrasion level is 2 or less, the pH range is from 5 to 9 and the resistivity is greater than 1500 ohm-cm or greater than 5000 ohm-cm with a pH of 4.5 to 5. The soil side of all but six of the samples has 100 percent coating remaining with only one of the six having been exposed for less than 60 years. The water side of the samples exhibit varying degrees of degradation due to water corrosivity, wet and dry cycling, bedload and water flow. Of the few sites with pitting, it was found mainly on the upstream side of the corrugation in the invert. All pipes are currently functioning as intended at this point in their life and would be expected to meet the design service life of 75 or 100 years.