Polymer Coating Overview

The 10/10 grade (10 mils thickness, each side)is the primary product used. Polymer coating provides excellent adhesion to the base steel and extended corrosion and abrasion resistance. The service life recommendations are based on extensive lab and field tests. While polymer coated CSP has not been in use quite as long as the galvanized or aluminized coatings, polymer CSP installations still go back to nearly 40 years ago.

The performance of polymer CSP has been monitored by Corrpro and found to have essentially no deterioration despite installation in some extreme environments. NCSPA and The Dow Chemical Company, the manufacturer of TRENCHCOAT™ Protective Film, have conducted laboratory tests to provide additional data related to the service life of polymer coated CSP. Sites contained environmental conditions with resistivity as low as 100 ohm-cm and pH as low as 2.1.

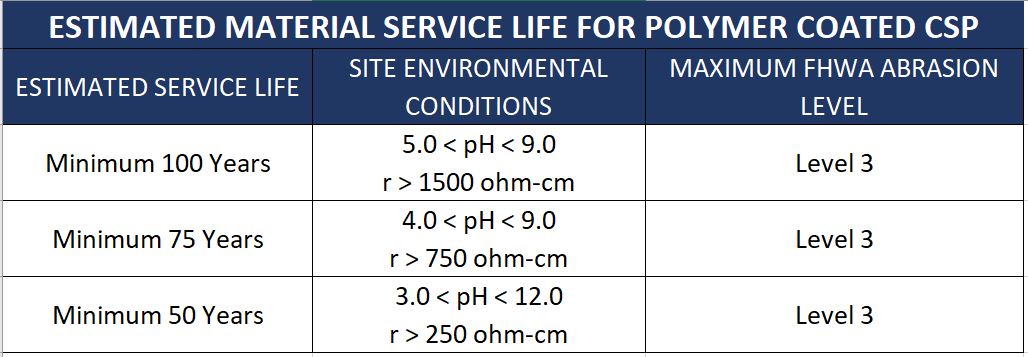

Recent testing indicates polymer coated CSP can withstand abrasion level three conditions. Since polymer is a barrier coating, it exhibits uniformly predictable durability performance within defined environmental ranges. These criteria and the defined ranges for polymer coated pipe are shown in figure 3. Polymer coated pipe operating within these ranges can achieve a 100-year service life based on the current evaluations of installations in the recommended ranges of adverse conditions for nearly 40 years.

Note: Corrosion conditions at the extreme limits of the environmental ranges may require adjusting service life values

For more information download our Pipe Selection Guide found here.

Polymer Applications

DOT Information

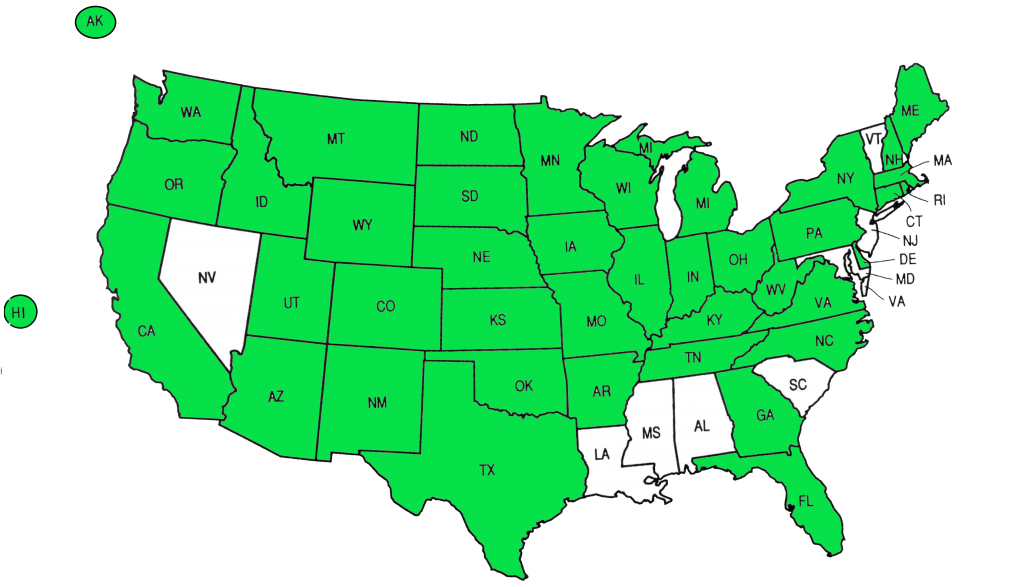

The below is a map of the states that currently accept Polymer coated pipe and plate in their specs.

Success Stories

Polymer Coated Stormwater Detention Systems: Enhancing Efficiency at Lambert Landing

Restoring Fish Habitats: Culvert Replacement Project in Alabama Helps Protect Endangered Species

Overcoming Landslide Challenges: A Speedy Solution for the Anatolian Highway

Studies, Resources & Marketing Materials

- Results of Testing of Polymer Precoated Steel Sheet According to ASTM A742 – Over 50 years ago, the first plain galvanized corrugated steel pipe was coated with polymer laminate to boost performance and allow for use in more aggressive environments. Providing even greater resiliency to the most sustainable product on the market, steel. This report describes the testing that was conducted on eight coating systems of various zinc weights and polymer coating thickness in comparison to the Requirements for Polymer Coating (Section 7) of ASTM A742/A742M, Standard Specification for Steel Sheet, Metallic Coated and Polymer Precoated for Corrugated Steel Pipe.

- Polymer Coated Structural Plate and Fastener Testing – Polymer coated corrugated steel structural plate has been developed as a more durable and resilient alternative to galvanized steel structural plate. Corrugated plate structures are assembled using threaded fasteners which also receive a polymer coating. This report describes testing performed to support the development of a new ASTM specification for polymer-coated corrugated steel structural plate

- Superior Abrasion Resistance of Polymer Coated Corrugated Steel Pipe – Superior Abrasion Resistance of Polymer Coated Steel Pipe – Over 40 years ago the corrugated steel pipe industry developed a polymer precoat protective film that significantly extends the service life of galvanized CSP and provides over a century long solution in as harsh as level 3 abrasive environments. Based on extensive experience, laboratory and field testing; polymer coated corrugated steel pipe has proven to be a strong, reliable, sustainable part of our nation’s infrastructure. Polymer coated corrugated steel pipe fabricated to meet specifications, which can be evidenced by qualification and routine quality assurance testing; has, can, and will provide not only value but the necessary service life performance under our great nation’s highways ensuring the safety of future generations.

- Long-Term Field Investigation of Polymer Coated Corrugated Steel Pipe – A report by Elzly Technology Corporation documenting the performance and environmental conditions of polymer coated CSP in 5 states (AR, LA, MI, NY, and WI) around the country.

- Field Performance Evaluation of Polymer Coated Pipe in MN – A report documenting the performance and environmental conditions of polymer coated CSP in the state of Minnesota of sites nearly 40 years old.

- Field Performance Evaluation of Polymer Coated Structures in NY – A report by Corrpro Companies, Inc. documenting the performance and environmental conditions of polymer coated/asphalt paved CSP in New York state.

- Field Performance Evaluation of Polymer Coated Structures in WI – A report by Corrpro Companies, Inc. documenting the performance and environmental conditions of polymer coated CSP in Wisconsin of sites up to 27 years old

- Service life upgrades – rehab

ASTM STANDARDS –

- A742/A742M-18 Standard Specification for Steel Sheet, Metallic Coated and Polymer Precoated for Corrugated Steel Pipe

- A762/A762M-19 Standard Specification for Corrugated Steel Pipe, Polymer Precoated for Sewers and Drains

- A796/A796M-17a Standard Practice for Structural Design of Corrugated Steel Pipe, Pipe-Arches, and Arches for Storm and Sanitary Sewers and Other Buried Applications

- A798/A798M-17 Standard Practice for Installing Factory-Made Corrugated Steel Pipe for Sewers and Other Applications

- A930-09(2014) Standard Practice for Life-Cycle Cost Analysis of Corrugated Metal Pipe Used for Culverts, Storm Sewers, and Other Buried Conduits

- A1113-20 Standard Specification for Corrugated Steel Structural Plate, Polymer-Coated, for Field-Bolted Pipe, Pipe-Arches, and Arches

Want To Learn More?

Contact us today to schedule an in person presentation. Simply fill out the below form and someone will contact you shortly.