Corrugated steel pipe (CSP) has been used successfully for more than 100 years in storm sewer and culvert applications throughout North America and around the world. Over the past 50 years, CSP has gone through an evolutionary process resulting in better materials, with a longer service life in challenging environments. This page outlines the different coatings available on a CSP for service life extension.

Polymer Coated CSP

Polymer coated (AASHTO M245, ASTM A742) is a laminate film that is applied over protective metallic coatings, typically galvanized. The 10/10 grade (10 mils thickness, each side) is the primary product used. Polymer coating provides excellent adhesion to the base steel and extended corrosion and abrasion resistance. The service life recommendations are based on extensive lab and field tests. While polymer coated CSP has not been in use quite as long as the galvanized or aluminized coatings, polymer CSP installations still go back to nearly 40 years ago.

coating provides excellent adhesion to the base steel and extended corrosion and abrasion resistance. The service life recommendations are based on extensive lab and field tests. While polymer coated CSP has not been in use quite as long as the galvanized or aluminized coatings, polymer CSP installations still go back to nearly 40 years ago.

The performance of polymer CSP has been monitored by Corrpro and found to have essentially no deterioration despite installation in some extreme environments. NCSPA and The Dow Chemical Company, the manufacturer of TRENCHCOAT™ Protective Film, have conducted laboratory tests to provide additional data related to the service life of polymer coated CSP. Sites contained environmental conditions with resistivity as low as 100 ohm-cm and pH as low as 2.1.

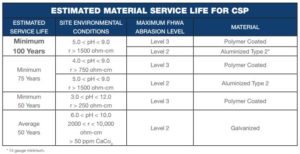

Recent testing indicates polymer coated CSP can withstand abrasion level three conditions. Since polymer is a barrier coating, it exhibits uniformly predictable durability performance within defined environmental ranges. These criteria and the defined ranges for polymer coated pipe are shown in figure 3. Polymer coated pipe operating within these ranges can achieve a 100-year service life based on the current evaluations of installations in the recommended ranges of adverse conditions for nearly 40 years.

For more information on Polymer Coated CSP please visit our Studies & Reports page. This page is a vast resource for different studies related to CSP and it’s service life.

Note: Corrosion conditions at the extreme limits of the environmental ranges may require adjusting service life values

Zinc-Coated (Galvanized)

Zinc-coated (Galvanized) Steel (AASHTO M36, ASTM A929) is produced with a coating weight of 610 g/m² (2 oz/ft²) of surface (total both sides) to provide zinc coating thickness of 43 µm (0.0017in.) on each surface.

The zinc’s excellent resistance to corrosion is due to the galvanizing, which provides a barrier coating, and through its cathodic protection or the formation of protective films on zinc during exposure. High corrosion rates in strongly acidic and strongly alkaline solutions can be attributed to the absence of film on the metal surface (stable films are present on the surface when the corrosion rates are low).

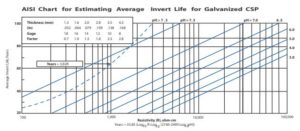

The service life of zinc-coated galvanized is determined using the American Iron and Steel Institute (AISI) Chart for Estimating Average Invert Life for Galvanized CSP (noted below). This chart predicts a variable service life based on pH and resistivity of water and soil and has been an industry standard for many years. The service life of CSP can be reasonably predicted based on the environmental conditions discussed above. This chart is based on 16 gage galvanized CSP with a 610 g/m²(2 oz/ft²) coating and can be applied to other thicknesses with the appropriate factor.

Aluminum Coated Type 2

Aluminum Coated Type 2 (AASHTO M274, ASTM A929) is a pure aluminum coating (no more than 0.35 percent silicon). It is produced with a coating weight of 305 g/m² (1 oz/ft²) of surface (total both sides) to provide a coating thickness of 48 µm (0.0019 in.) on each surface. The aluminum coated type 2 (ALT2) is the most widely used supplemental coating for CSP. “Aluminum is a reactive metal, but it develops a passive aluminum oxide coating or film that protects it from corrosion in many environments.” This film is quite stable in neutral and many acid solutions but is attacked by alkalies greater than a pH of 9. From a corrosion standpoint, aluminum has an advantage over galvanized in lower pH and in soft water conditions due to the formation of the oxide film. The coatings are essentially equal under abrasion and in waters where the zinc oxide film forms rapidly.

Aluminum coated type 2 CSP has been installed at thousands of sites over the past 50 years and many of these sites have been and are still being monitored for performance. Recent AK Steel research has indicated that 14 gage ALT2 CSP can achieve a 100-year service life when the environmental conditions have a pH of 5 to 9 and a resistivity greater than 1500 ohm-cm.

For more information on Polymer Coated CSP please visit our Studies & Reports page. Study topics range from the performance of aluminized type 2 steel pipe in storm sewer application to the service life evaluation of corrugated steel pipe.

Additional Coatings

Additional service life can be provided by increasing the thickness of the base steel in accordance with the factors shown in the Chart for Estimating Average Invert Service Life or with the use of additional coating systems. Add-on service life values are provided in figure 4, titled Service Life Add-ons for Supplemental Pavings and Coatings. These coatings offer advantages over metallic coatings in the form of increased abrasion resistance, wider environmental ranges and longer service life. Inherent in these coatings is less variability in performance which is why specific add-on service life values are recommended under various abrasion levels.

Asphalt Coated (AASHTO M190, ASTM A849)

An asphalt coating is applied to the interior and exterior surface of the pipe with a minimum thickness of 1.3 mm (0.05 in.) in both fully coated and half coated. Asphalt coatings are generally used for soil-side protection but also provide additional waterside protection. Numerous studies have concluded that asphalt coating typically provides 10 years additional service life to the inside of the pipe. Asphalt coatings provide much higher service life on the soil-side and inherently extend the environmental ranges for soil conditions. According to Corrpro, “study results indicate that the addition of an asphalt coating may have provided a soil side service life in excess of 100 years.”

Fully Lined with Asphalt Material (ASTM A849)

An asphalt material is used to fill the corrugations and provide a minimum thickness of 3.2 mm (1/8 in.) above the crest of the corrugations, providing a smooth surface over the entire pipe interior. Asphalt linings are typically used for improved hydraulic performance but also provide additional abrasion protection and extended service life. The use of asphalt material and metallic-coated steel provide higher service life values.

Invert Paved with Asphalt Material (AASHTO M190, ASTM A849)

An asphalt material is used to fill the corrugations and provide a minimum thickness of 3.2 mm (1/8 in.) above the crest of the corrugations for at least 25 percent of the circumference of round pipe and 40 percent of the circumference for pipe arch. Asphalt paved CSP provides both additional service life and added abrasion protection on the water side of the pipe. Based on several studies, coated and paved is considered to provide an additional 30 years service life under most abrasion levels. This is considered a very conservative estimate for non abrasive and low abrasion (levels 1 and 2).

Invert Coated with Polymerized Asphalt Material (ASTM A849)

A polymer modified asphalt material is used to fill the corrugations and provide a minimum thickness of 1.3 mm (0.05 in.) above the crest of the corrugations for at least 25 percent of the circumference of round pipe and 40 percent of the circumference for pipe arch. Generally used for invert treatments only, polymerized asphalt provides improved adhesion and abrasion resistance over standard asphalt products. Full scale abrasion tests conducted by Ocean City Research indicate no deterioration of the coating under moderate abrasion (level 3). Based on independent test lab results using test method ASTM A926, results indicate that the commercially available polymerized asphalt coating lasts at least 10 times longer than standard asphalt coating and at least three times longer than standard culvert coated and paved.

Polymer Coated and Asphalt Paved

Polymer coated and asphalt paved benefits from the excellent adhesion of the polymer coated to the base steel and the subsequent adhesion of the paving to the precoat. According to laboratory and field tests the combination of the three coatings results in a pipe which is highly resistant to acidic effluent. The bituminous material has much better adhesion to the polymeric coating than it does to the galvanized coating.

Polymer Coated with Polymerized Asphalt Invert Coated

Full scale abrasion tests conducted by OCR show equal performance of the polymerized asphalt over polymer coated when compared to standard asphalt paved. This system has the same bonding characteristics as the polymer coating and asphalt paving. Field sites also indicate improved adhesion.

Invert Paved with Concrete Material (ASTM A849, ASTM A979)

A 75 mm (3 in.) thick concrete layer is placed in the installed pipe for at least 25 percent of the circumference of round pipe and 40 percent of the circumference for pipe arch. Concrete inverts provide extreme abrasion protection and extended service life. According to Stratfull, “metal pipe with an invert paved with concrete should provide an indefinite service life if it is of sufficient width, thickness and quality. By calculation, a 4-inch thick coating over the invert steel could be expected to postpone its initial time to corrosion by approximately 7.7 times greater than a 3/4 inch coating.”

Fully Lined with Concrete Material (ASTM A849, ASTM A979)

A high strength concrete material is used to fill the corrugations and provide a minimum thickness of 3.2 mm (1/8 in.) above the crest of the corrugations providing a smooth surface over the entire pipe interior. Concrete linings are typically used for improved hydraulic performance but also provide additional abrasion protection and extended service life. The use of high strength concrete and metallic coated steel provide high service life values.

For more information download our Pipe Selection Guide found here.