OverviewALT2 ApplicationsDOT InformationSuccess StoriesResources

Aluminum Coated Type 2

Aluminum Coated Type 2 (AASHTO M274, ASTM A929) is a pure aluminum coating (no more than 0.35 percent silicon). It is produced with a coating weight of 305 g/m² (1 oz/ft²) of surface (total both sides) to provide a coating thickness of 48 µm (0.0019 in.) on each surface. The aluminum coated type 2 (ALT2) is the most widely used supplemental coating for CSP. “Aluminum is a reactive metal, but it develops a passive aluminum oxide coating or film that protects it from corrosion in many environments.” This film is quite stable in neutral and many acid solutions but is attacked by alkalies greater than a pH of 9. From a corrosion standpoint, aluminum has an advantage over galvanized in lower pH and in soft water conditions due to the formation of the oxide film. The coatings are essentially equal under abrasion and in waters where the zinc oxide film forms rapidly.

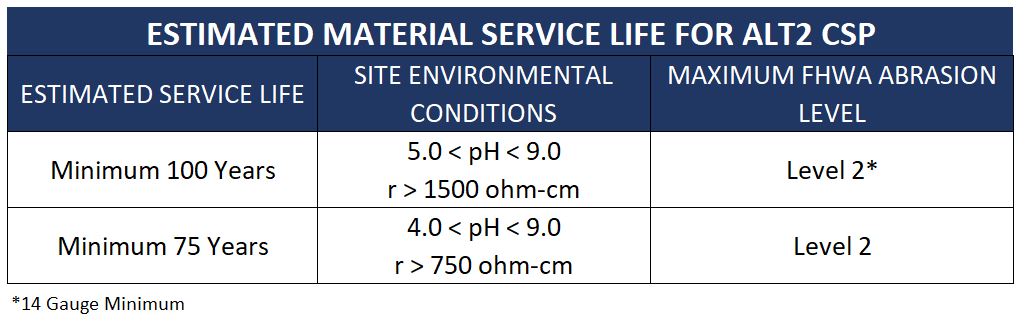

Aluminum Coated Type 2 (AASHTO M274, ASTM A929) is a pure aluminum coating (no more than 0.35 percent silicon). It is produced with a coating weight of 305 g/m² (1 oz/ft²) of surface (total both sides) to provide a coating thickness of 48 µm (0.0019 in.) on each surface. The aluminum coated type 2 (ALT2) is the most widely used supplemental coating for CSP. “Aluminum is a reactive metal, but it develops a passive aluminum oxide coating or film that protects it from corrosion in many environments.” This film is quite stable in neutral and many acid solutions but is attacked by alkalies greater than a pH of 9. From a corrosion standpoint, aluminum has an advantage over galvanized in lower pH and in soft water conditions due to the formation of the oxide film. The coatings are essentially equal under abrasion and in waters where the zinc oxide film forms rapidly.Aluminum coated type 2 CSP has been installed at thousands of sites over the past 50 years and many of these sites have been and are still being monitored for performance. Recent AK Steel research has indicated that 14 gage ALT2 CSP can achieve a 100-year service life when the environmental conditions have a pH of 5 to 9 and a resistivity greater than 1500 ohm-cm.

For more information download our Pipe Selection Guide found here.

ALT2 Applications

DOT Information

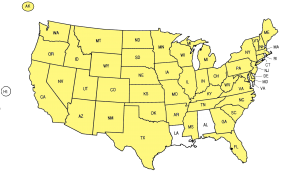

The below is a map of the states that currently accept ALT2 coated pipe and plate in their specs.

Success Stories

CSP & Pipe Arch Project of the Year Winner: Town of Lyons Bridge Replacement

By: Metal Culverts Inc. The town of Lyons in Walworth County Wisconsin was faced with the task of replacing one of their bridges that had ... Read more

2019 Project Of The Year Winners

Our 7th annual Project of the Year awards was graced with 25 amazing projects in 7 categories this year! This was a big year ... Read more

2019 Safety Award Winners

In the 32nd year of the Safety Awareness program, NCSPA is proud to present 47 plants with no lost workdays. In all 8 member companies ... Read more

Studies, Resources & Marketing Materials

- The Measured Performance of Aluminized Type 2 Steel Pipe in Storm Sewer Applications in the North Georgia Region – A research project on the durability of Aluminized Steel Type 2 pipe

installed in the metro Atlanta area has resulted in an outstanding report of the product’s performance.

installed in the metro Atlanta area has resulted in an outstanding report of the product’s performance. - Durability of Aluminized Type 2 Corrugated Steel Pipe Exposed Throughout the United States – A report by Elzly Technology Corporation documenting the performance and environmental conditions of aluminized type 2 coated CSP in 11 states and parts of Canada.

- Service Life – ALT2 Field Reports

- EFFECTS OF GAGE ON PIPE DURABILITY: Based on 75 Years Minimum Service Life at 16 Gage – For Worst-Case Conditions Within The Recommended pH/Resistivity Ranges

- Meeting New Durability Standards and Expanding Environmental Limits with Corrugated Steel Pipe

- The Measured Performance of Aluminized Type 2 Steel Pipe in Storm Sewer Applications in the North Georgia Region – A research project on the durability of Aluminized Steel Type 2 pipe

installed in the metro Atlanta area has resulted in an outstanding report of the product’s performance.

installed in the metro Atlanta area has resulted in an outstanding report of the product’s performance.